The impact of LiDAR on accuracy and workflow management - insights from Prince Tetteh

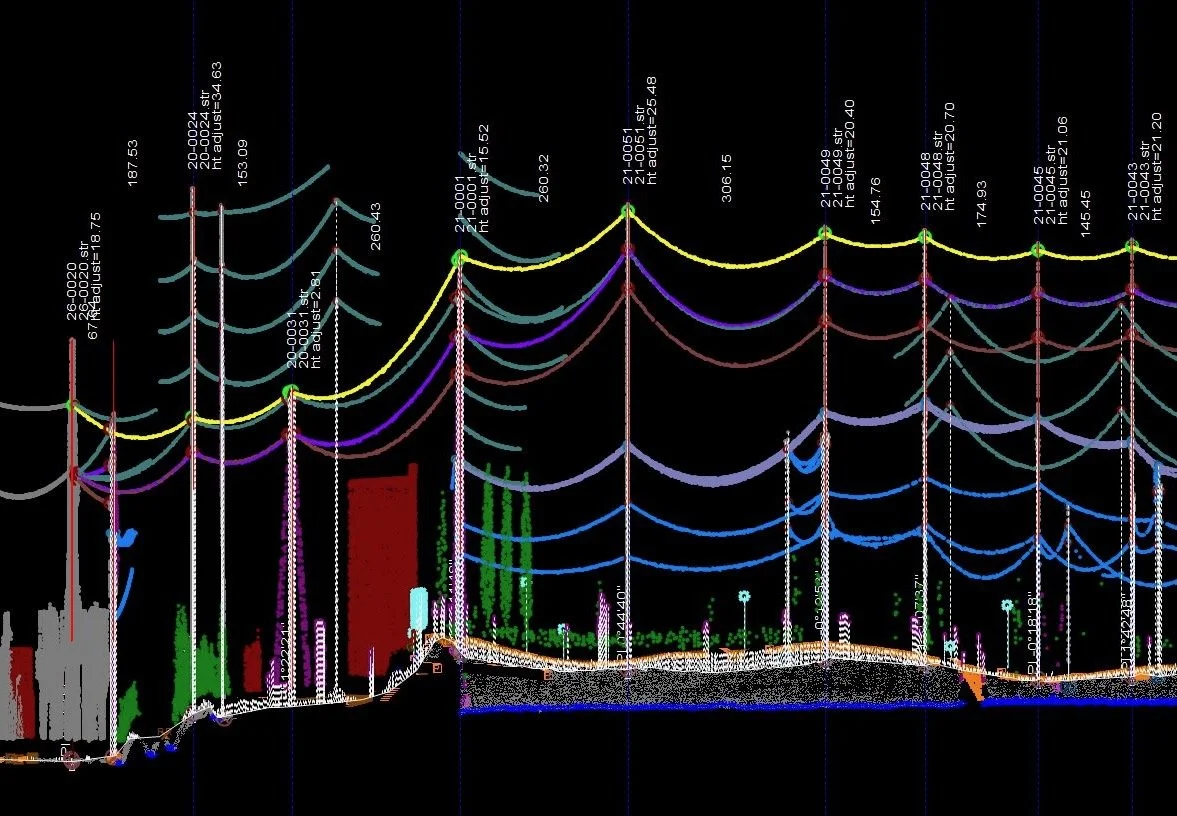

Riegl LiDAR sensor used to support PLS-CAD utility mapping

Can LiDAR do anything?

This is a question that Prince Tetteh, DroneView Technologies Mapping Production Manager, deals with directly and indirectly all the time. While LiDAR (which is an acronym for light detection and ranging) has a history that goes back to the 1960s, the technology has become that much more powerful thanks to new sensors that capture even more information. Additionally, LiDAR sensors on a drone provide an entirely new perspective, enabling the creation of high-accuracy mapping products that can impact planning and improve safety.

However, unlocking these efficiencies isn’t just a matter of utilizing LiDAR for any and every project. What level of detail and accuracy is needed? Would airborne, terrestrial, or mobile LiDAR make the most sense for a given project? How can topo maps create value? What are the distinctions between cost? Those are the specifics that Tetteh works through with surveyors and engineering firms to determine what tools are best for their aerial mapping or geospatial project.

Understandings and Expectations

Beginning his career as a Stereoplotter Operator that saw him compiling from film imagery, Tetteh has seen the evolution of the industry and technology firsthand. In those early days, teams would need to time their projects based on the season to capture details like road edges or manhole covers, but the full inception of LiDAR changed all of that. Newer LiDAR sensors have further improved accuracy and allowed for mapping in various conditions, but these additional capabilities have also increased client expectations for higher accuracy levels.

“The biggest change is that now we can work all year round, instead of waiting for leaf-off conditions,” Tetteh said. “It wasn’t an immediate change though, because the technology was so expensive at the time. The prices have come down to a manageable level so we’re at the point where we use LiDAR on almost every product.”

Prince Tetteh alongside an example of one of the many types of products delivered by the DroneView Technologies team.

This switch has allowed the DroneView Technologies team to provide year-round mapping services. Accuracy expectations quickly changed as a result of these sensor innovations, but a few years later, drones changed the paradigm once again.

Drones, capable of flying at various altitudes, enabled teams to capture data that enhanced topographic mapping and volume calculation capabilities. Drones were also able to access challenging terrains that aren’t a fit for ground crews. However, the reality is that large-scale projects cannot be effectively handled by drones, which means selecting the right tool for the right job is paramount. Prioritizing an understanding of the end product's use and the client's expectations is crucial for establishing and managing what can be complex workflows.

“LiDAR is great because it can penetrate vegetation, but the thickness of the vegetation influences how far it can get to the ground,” Tetteh explained. “It often surprises people to hear it, but there are limitations of LiDAR in vegetated areas, which is why we spend a great deal of time talking about accuracy needs and expectations with our clients. The accuracy of the data is impacted by the density and height of the vegetation. Dense vegetation can obscure the ground surface, leading to less accurate measurements. These are all factors we consider when planning a LiDAR survey to ensure that we provide the desired level of accuracy in the final product.”

This approach speaks to the clear communication around requirements that Tetteh and the DroneView team establish before any project starts. It involves tailoring their LiDAR offerings to meet specific project needs, whether through traditional stereo mapping or advanced LiDAR solutions. It involved using helicopters or fixed-wing aircraft if the site is large enough. Regardless of the specific acquisition tool, a commitment to quality control sets DroneView Technologies apart from the competition.

A commitment to high-quality data through rigorous quality control processes

Civil engineering and construction materials companies recognize the power of high-accuracy mapping solutions like those offered by DroneView Technologies. These precise mapping products help them optimize operations, improve safety, and make informed decisions. Establishing what these assets need to be before the project starts is an essential part of the process, but the quality control rigors that DroneView goes through highlight what makes their offerings different.

“During every stage of a project, we have QC routines to make sure that the data is correct and we don’t have any mistakes,” Tetteh said. “At every stage, which includes when the LiDAR is flown to when the control is acquired, we’re making sure the imagery is right. We check the imagery to make sure there is no shadowing. We compare the LiDAR to the ground control points to make sure that everything lines up. The QC in production is in some ways even more rigorous since we’re probably one of the few companies still relying on old-style stereo mapping, because we've come to realize that nothing compares to the human eye.”

Tetteh explained that the DroneView team’s QC process to run traditional aerial triangulation involves people in a way others have automated, ensuring the accuracy of the information related to ground control. After establishing accurate ground control points, the team maps all of the imagery and lines it up with LiDAR data to ensure precise alignment between the two datasets. This meticulous approach guarantees accurate Digital Terrain Models (DTMs) by comparing them to LiDAR and planimetric features. They also verify that the planimetric features correspond to those visible in the imagery, further enhancing the overall accuracy of the final product.

The team then makes sure that the lines are snapped properly so there’s no discrepancy between elevation points. Because they’re flying year-round, the data needs to accurately reflect conditions where the ground is obscured through trees, through high brush or through shadows. This rigorous QC process is what ensures they have what they need to provide final delivery, which can take a variety of formats.

“We most often deliver AutoCAD files to our clients. These files are separated into 2D PLAN, 3D DTM, Contour, Civil 3D surface and XML files,” Tetteh said. “We also have clients that require us to deliver Microstation files. As part of all our deliverables, we provide Orthophotos of the project site in Geo tiff and Mrsid formats. Other formats can also be delivered by request.”

Timing around these deliveries depends on the project but also on the preferred frequency. That timing is especially critical with stockpile measurements, as stockpiles are not static. Rain and various other elements mean the stockpiles change, sometimes daily. DroneView Technologies can provide timely snapshots of project sites, enabling comparisons of current volumetric data to historical data. This information can be invaluable for refining project schedules and timelines.

Tetteh mentioned that the primary DroneView Technologies client base includes engineering firms, aggregate companies, and transmission line operators but their unique approach to combining traditional photogrammetry and LiDAR can open doors in various other sectors. It’s a difference that current clients have noticed thanks to the highly detailed, highly accurate maps that are the result of a QC process few others can compare with.

“Just this week one of our clients said the files we were giving them were cleaner than what they used to getting, so that tells me we’re doing something right,” Tetteh said. “It can be a bit more time-consuming on our side, but feedback like that makes it all worthwhile. We don't shy away from challenges.”

Have a question for Prince? Get in touch with the DroneView team or connect with him on LinkedIn to ask.